Product Overview:

This machine is a new type, high precision mixing equipment, widely used in pharmaceutical, chemical, feed and other industries of all kinds of powder material mixing.

The machine has a set of motor and cycloidal pinwheel reducer to complete the rotation, the use of two screw asymmetrical mixing, so that the material mixing range is large, mixing speed is fast, and the material mixing ratio is very large. The material contact parts of the machine are made of stainless steel.

The compound movement of the material in the cone is caused by the rotation and rotation of the spiral, which mainly produces four forms of movement:

1. The spiral rotates along the wall so that the material moves in a circle along the conical wall;

2. The spiral rotation causes the material to spiral up from the bottom of the cone;

3. The combined motion of spiral and rotation causes part of the material to be absorbed into the spiral cylinder and part of the material in the spiral cylinder to be radially discharged to the cone by the centrifugal force of spiral rotation;

4. Rising materials fall under their own gravity. The four movements generate convection, shear and diffusion in the mixer, so as to achieve the purpose of rapid and uniform mixing.

Equipment process demonstration:

Product features:

1. Can be equipped with flying knives and spray atomization assembly to meet special process requirements

2. The discharge valve has two modes: manual and pneumatic

3. Special materials can increase motor power (weight)

Product application:

Applied in chemical, pharmaceutical, pesticide, dye, petroleum, metallurgy, building materials and other industries, including powder to powder (solid solid), powder to liquid (solid-liquid), liquid to liquid (liquid-liquid) mixing, reaction, drying, and cooling.

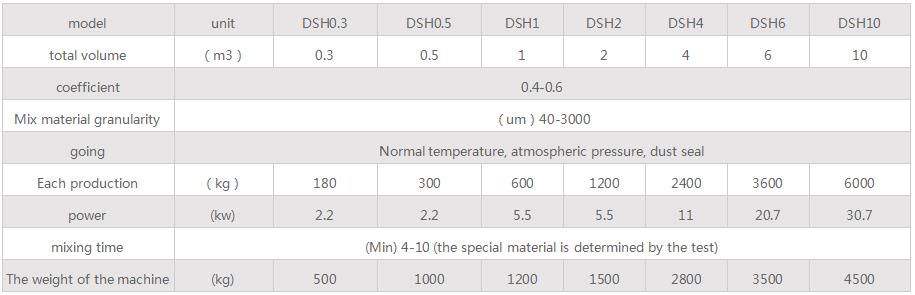

Technical specifications:

Cooperative clients: