The GXZ series high-efficiency rotating thin film evaporator, also known as the scraper evaporator, is a new type of high-efficiency evaporator that uses a rotating scraper to force film formation and can perform falling film evaporation under vacuum conditions. It has a high heat transfer coefficient, high evaporation intensity, short overcurrent time, and high operational flexibility, making it particularly suitable for the evaporation concentration, degassing and desolvation, distillation and purification of thermosensitive materials, high viscosity materials, and easily crystallized granular materials. Therefore, it has been widely used in industries such as chemical, petrochemical, pharmaceutical, pesticide, daily chemical, food, and fine chemical.

Our company has been manufacturing this type of equipment for many years and has accumulated rich experience in manufacturing and use. For a long time, we have closely integrated with customers' production reality and market demand to meet their process requirements, select reasonable and suitable structures, and ensure superior and reliable manufacturing quality. We have continuously improved and perfected our tooling equipment, testing methods, and product design, and have achieved remarkable results. Our technical level and product quality are leading in China.

The material enters the evaporator radially from above the heating zone, and is distributed to the heating wall of the evaporator through the distributor. Then, the rotating scraper continuously and uniformly scrapes the material into a thin and uniform liquid film on the heating surface, and pushes it downwards in a spiral shape. During this process, the rotating scraper ensures continuous and uniform liquid film to generate high-speed turbulence, and prevents the liquid film from coking and scaling on the heating surface, thereby improving the total transfer coefficient. Light components are evaporated to form a steam stream that rises and passes through a vapor-liquid separator to reach an external condenser directly connected to the evaporator. Heavy components are discharged from the cone at the bottom of the evaporator.

A unique distributor not only can evenly flow the materials to the inner wall of the evaporator to prevent the materials from splashing into the evaporator and injecting steam, but also can prevent the newly entered materials from flashing here, which is conducive to the elimination of foam. Materials can only evaporate along the heating surface. A centrifugal separator designed based on material characteristics is installed at the upper part of the scraper evaporator to separate the liquid droplets in the rising steam flow and return them to the distributor.

Due to the movement of the scraper, the material is continuously scraped into a film on the evaporation surface, and the material is in a turbulent state to achieve the effect of film evaporation. According to the viscosity and other characteristics of the material, the evaporator can be divided into the following types of scraper:

Active scraper: Active scraper is a basic and common form of scraper. The forms of the movable scraper are: SR type, SL type, DR Type, DL type, and the liquid channel Angle is 30°, 45° or 60°.

Fixed scraper: fixed scraper are made of metal material, it is rigidly connected to the rotor, the length of the scraper is the same as the evaporation cylinder body, the gap between the rotary scraper and the inner wall of the i evaporation cylinder body is only 1+2mm, requiring higher processing and installation accuracy, it is suitable for ultra-high viscosity and easy to foam materials evaporation concentration, dissolution or purification.

Spiral scraper: The scraper is suitable for the concentration of poor fluidity, easy scaling and extremely high viscosity materials. When the rotor rotates, the thrust of the spiral scraper makes the concentrated material flow down smoothly.

Hinge scraper: Hinge scraper is suitable for materials that are easy to scale on the heating surface or have medium viscosity.

The rotating thin film evaporator has the following unique advantages that cannot be compared to conventional film evaporators:

1. Minimal pressure loss

In an efficient rotating thin film evaporator, the material flow and the secondary evaporation steam flow are two independent channels: the material descends along the inner wall of the evaporator cylinder (forced film formation), while the secondary steam evaporated from the evaporation surface leaves the evaporator almost unobstructed from the central space of the cylinder, resulting in minimal pressure loss (or resistance drop).

2. Can operate under true vacuum conditions

Due to the extremely low resistance of the secondary vapor from the evaporation surface to the condenser, the evaporation surface on the inner wall of the entire evaporation cylinder maintains a high vacuum degree (up to -750mmHg), almost equal to the vacuum degree at the outlet of the vacuum system. As the vacuum degree increases, the boiling point of the processed material is effectively reduced.

3. High heat transfer coefficient, high evaporation intensity

The decrease in boiling point increases the temperature difference with the heat medium; The turbulent liquid film reduces thermal resistance; Simultaneously suppressing material coking and scaling on the wall, and also improving the heat transfer coefficient of the evaporator wall; Therefore, the heat transfer coefficient of the high-efficiency rotating thin film evaporator can reach up to 8000KJ/h.m2. ℃, resulting in a high evaporation intensity.

4. Low temperature evaporation

Due to the high vacuum level maintained inside the evaporator, the boiling point of the processed material is greatly reduced, making it particularly suitable for low-temperature evaporation of thermosensitive materials.

5. Short overcurrent time

The overcurrent time of the material in the evaporator is very short, about 10 seconds; For commonly used activity scrapers, there are guiding grooves on the end face of the material being scraped, and the angle of inclination is usually 45 ℃. Changing the angle of inclination can change the flow time of the material. Under the scraping of the scraper, the material spirals down and leaves the evaporation section. Shorten the overcurrent time and effectively prevent the decomposition, polymerization, or deterioration of the product during the evaporation process.

6. Low grade steam can be utilized

Steam is a commonly used heat medium. By reducing the boiling point of the material, the temperature of the heating medium can be lowered while ensuring the same Δ t. Utilizing low-grade steam is beneficial for the comprehensive utilization of energy.

7. Strong adaptability and easy operation

The unique structural design allows this product to handle materials with high viscosity, particle content, thermal sensitivity, and easy crystallization that are difficult to handle with conventional evaporators.

The rotary thin film evaporator has high operational flexibility, stable operating conditions, low maintenance workload, and easy maintenance.

Note:

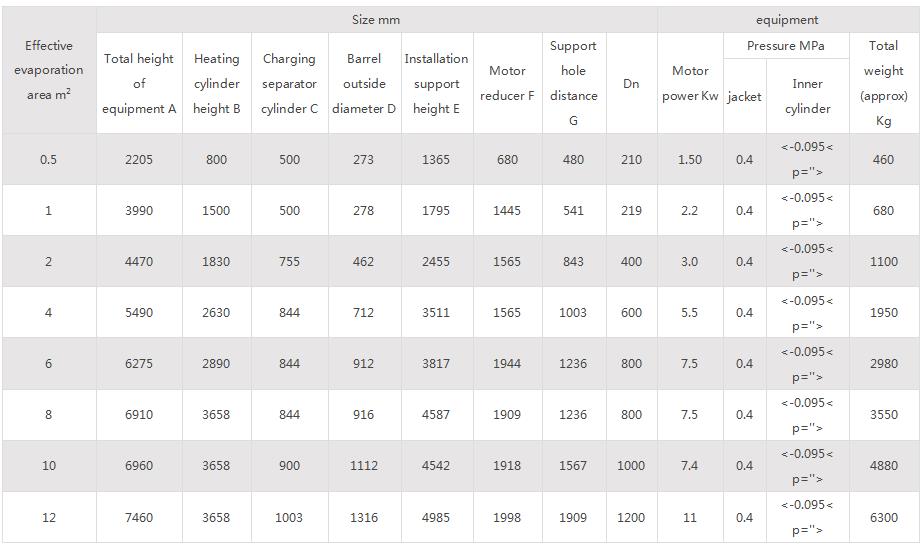

1. The above dimensions and the actual equipment may change slightly for reference, and the drawings provided by our company shall prevail after ordering;

2. Table weight D indicates the outer diameter of the jacket, Dn indicates the inner diameter of the evaporation cylinder;

3. Jacket pressure: generally according to 0.4MPa steam design, can also be designed according to user requirements, when using heat transfer oil, can also be designed;

4. Vacuum degree of evaporation inner cylinder: generally -0.09MPa(about -680mmHg), but also according to user needs, up to -0.095MPa(about -720mmHg) and -0.0986Mpa(about -750mmHg));

5. Main cylinder (the part in contact with the material) and jacket material: according to the user and actual needs, carbon steel, SUS304, 316L, 316Ti or titanium materials;

6. Total weight of equipment: not including material weight

Scraper type thin film evaporators have been widely used in heat exchange engineering. Especially for heat sensitive materials and short residence time heat exchange, the scraper is beneficial for heat exchange, and through different scraper designs, complex product distillation can be carried out. Scrap film evaporators have been used in the following fields for the purpose of evaporation concentration, desolvation, stripping, reaction, degassing, deodorization, etc., and have achieved good results.

Chinese and Western medicine: antibiotics, sugar solution, Chinese herbs such as Lei Gong Teng and Astragalus, intermediates such as methylimidazole and mononitrile amine;

Light industrial food: juice, gravy, color, flavor, flavor, enzyme preparation, lactic acid, xylose, starch sugar, potassium sorbate;

Oil daily chemical: ovophosphate, VE, cod liver oil, oleic acid, glycerin, fatty acids, waste lubricating oil, alkyl polyglycosides, alcohol ether sulfate, etc.

Synthetic resins: polyamide resin, epoxy resin, polyformaldehyde, PPS (polypropylene sebacate), PBT, acrylic formate;

Synthetic fiber: PTA, DMT, carbon fiber, polytetrahydrofuran, polyether polyol, etc.

Petrochemical: TDI, MDI, trimethylhydroquinone, trimethylol propane, sodium hydroxide, etc.

Pesticide biology: acetochlor, propachlor, chlorpyrifos, furanol, Methanoline, and other herbicides, insecticides, herbicides, mite control agents;

Wastewater: inorganic salt wastewater, etc.;