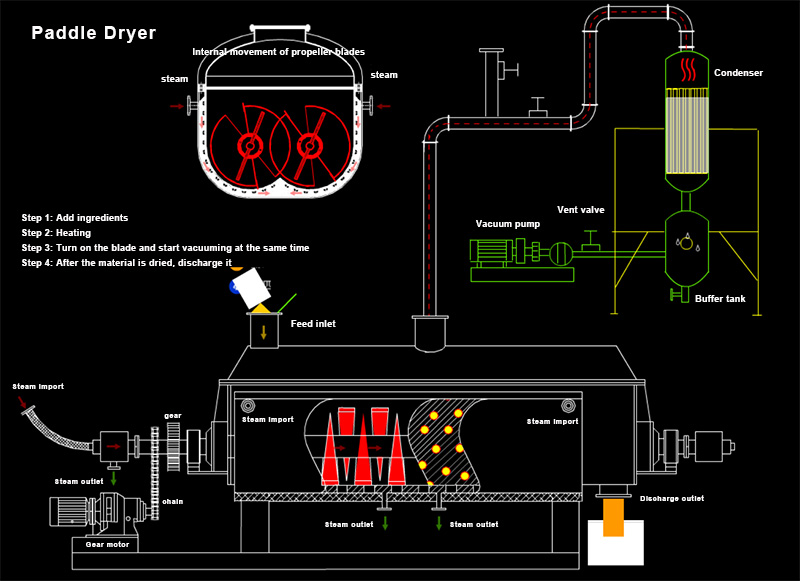

This product can indirectly heat or cool paste, granular, powdered, and slurry materials, and can complete unit operations such as drying, cooling, heating, sterilization, reaction, and low-temperature combustion. The special wedge-shaped stirring heat transfer blade in the equipment has high heat transfer efficiency and self-cleaning function of the heat transfer surface.

Wedge shaped hollow blades are densely arranged on the hollow shaft, and the heat medium flows through the blades through the hollow shaft. The heat transfer area within a unit effective volume is large, and the temperature of the heat medium ranges from -40 ℃ to 320 ℃. It can be steam or liquid, such as hot water, thermal oil, etc. Indirect conduction heating does not carry away heat with air, and the heat is used to heat the material. The heat loss is only the heat dissipation to the environment through the insulation layer of the device body. The wedge-shaped blade heat transfer surface has self-cleaning function. The relative motion between the material particles and the wedge-shaped surface produces a scrubbing effect, which can wash away the attached material on the wedge-shaped surface and maintain a clean heat transfer surface during operation. The shell of the blade dryer is Ω - shaped, and generally two to four hollow mixing shafts are arranged inside the shell. The shell has a sealed end cover and an upper cover to prevent material dust leakage and fully exert its function. The heat transfer medium flows through the shell jacket and hollow stirring shaft through the rotating joint. The hollow stirring shaft has different internal structures according to the type of heat medium to ensure the best heat transfer effect.

Petrochemical industry:polyolefin powder, polycarbonate resin, high and low density polyethylene, linear low density polyethylene, polyacetal particles, nylon 6, nylon 66, nylon 12, acetate fiber, polyphenylene sulfide, propylene based resin, polypropylene, engineering plastics, polyvinyl chloride, polyvinyl alcohol, polystyrene, polyester, polyoxymethylene, benzene& nbsp; Ethylene acrylonitrile copolymerization, ethylene propylene copolymerization

Environmental protection industry: sludge, electroplating wastewater sludge, boiler ash, sugar factory waste, pharmaceutical factory waste, monosodium glutamate factory waste, coal ash

Feed industry:soy sauce residue, bone based feed, distiller's grains, food scraps, apple pomace, orange peel, soybean meal, chicken bone feed, fish meal, feed additives, and biological sludge

Food industry:starch, cocoa beans, corn kernels, salt, modified starch, pharmaceuticals

Chemical industry:Soda ash, nitrogen phosphorus potassium compound fertilizer, kaolin, bentonite, white carbon black, carbon black, phosphogypsum, calcium sulfate, calcium nitrate, magnesium carbonate, sodium cyanide, sodium fluoride oxide, aluminum hydroxide, barium sulfate, calcium carbonate, molecular sieve, dye, saponin.

Large heat transfer area, compact structure, small footprint.

1、High utilization of heat energy, low energy consumption, loading capacity up to 70~80% of the cylinder volume, due to indirect heating, there is no large amount of air to take away the heat, the outer wall of the dryer and set a thermal insulation layer, evaporation of 1kg water only 1.2kg water vapor.

2、The wedge blade has self-cleaning ability, which can improve the heat transfer of the blade.

3、Wide applicability of materials, the use of different thermal media, you can deal with thermal sensitive materials, but also can deal with high temperature drying materials.

4、Commonly used media are: water steam, thermal oil, hot water, cooling water and so on. It can be operated continuously or intermittently, and can be used in many fields.

5、The operation is stable and the product is dry evenly. Due to the special expansion and stirring effect of the wedge blade, the material is fully in contact with the heat transfer surface, so that the temperature, humidity and mixing gradient of the material in the axial section are very small, which ensures the stability of the process.

6、The operation cost is low, the normal operation of the equipment only needs 1 person, low speed mixing and reasonable structure. The amount of wear is small and the maintenance cost is very low.

1、Shaanxi Max Agricultural Technology Co., Ltd

2、Shaanxi Aowen Instrument Equipment Co., Ltd