Product Overview:

The DWF series air jet belt dryer is suitable for drying materials with poor breathability, such as pulp drying, coating cloth drying, and board drying.

Working principle:

During operation, hot air is sprayed simultaneously from top to bottom onto the material on the conveyor belt through a jet stream. Due to the jet velocity of over 15m/s, the convective heat transfer film is extremely thin, the heat transfer coefficient is high, and the drying speed is fast. When this equipment is used with impermeable materials, the top jet airflow still returns to the top, and the bottom jet airflow still returns to the bottom, participating in the circulation. The airflow beam of breathable materials has strong penetration and diffusion inside the material. The use of heat sources can include steam, electricity, hot air stoves, and fuel flue gas.

Structural diagram:

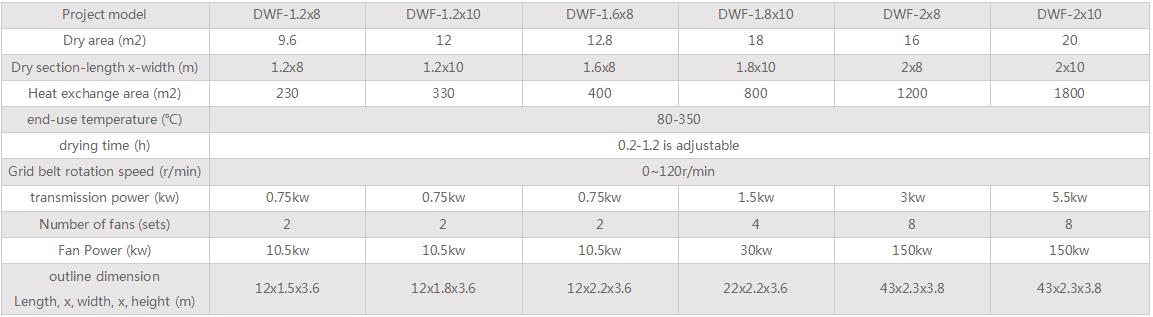

Technical parameters:

Note:

Due to its particularity, in the design process, the material properties, hot air temperature of the equipment, circulating gas volume, humidity, gas velocity, and gas stream form are not commonly used for most materials, and the actual differences are significant. Therefore, when placing an order, users should have detailed technical exchanges with our factory's technical personnel in order to make reasonable design plans, promote better equipment performance, and generate better benefits for users.

Cooperative customer