Closed-loop boiling dryer is a closed-loop system. At the beginning, start the fan, open the valve 1, close the valve 2, input the inert gas (generally nitrogen), replace the original air in the system, when the oxygen content in the system reaches the predetermined index, close the valve 1, open the valve 2. Since then, nitrogen in the system is used as a heat and mass transfer medium to complete the drying purpose of wet materials. After the organic solvent contained in the wet material is vaporized, it enters the condenser together with nitrogen, condenses the solvent into a liquid and flows into the storage tank. Nitrogen cannot be liquefied due to its low boiling point, and enters the next cycle under the push of the fan. The drying device in the closed cycle boiling dryer system can be selected according to the state and requirements of the material (also called boiling), it can also be a box-type boiling dryer, it can also be a vibrating fluidized bed dryer, and even an air dryer. Because these dryers are fluidized drying, the drying rate is higher and the drying time of the material is short.

1、the system is completely closed, basically no oxygen (content control). As mentioned above, the system of the closed-circuit boiling dryer is operated in a completely closed state, and neither (nor allow) leakage to the outside nor (do not allow) leakage to the inside. To this end, all parts of the system must be done, whether it is the pipe interface, or the inlet and outlet of the box; Whether it is in the positive pressure area or the negative pressure area; Both static and dynamic parts must be strictly sealed. The oxygen content in the system does not exceed the process requirements, which ensures the safety of fire prevention and provides a reliable guarantee for oxygen-afraid materials.

2、Zero emissions. Basically no exhaust emissions if the system is operated continuously

3、Solvent recovery. If the system can be continuously operated, the solvent recovery rate is very high (up to more than 98%), and its economic significance is self-evident.

4、high degree of automation. Our company in the system set up three parameters such as temperature, oxygen content, system pressure automatic control and over-limit alarm device, using PLC control, easy to operate.

1、Granulation in pharmaceutical industry: tablet granule, granule, capsule granule.

2、Food industry granulation: cocoa, coffee, milk powder, juice granules, condiments, etc.

3、Other industries: pesticide, feed, fertilizer, pigment, dye chemical industry, etc. Drying of wet materials in powder or granular form.

4、Coating: granule, pill protective layer, color preparation, slow release, film, enteric coating, etc.

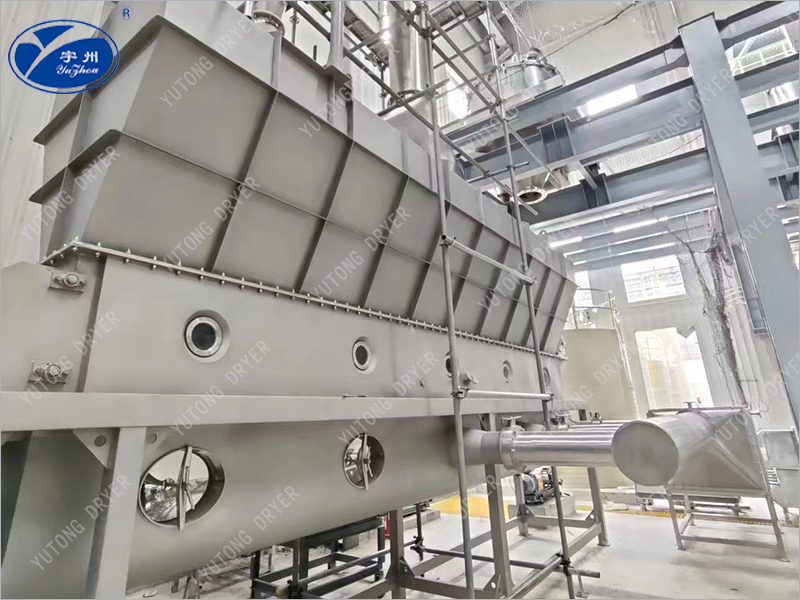

The closed cycle boiling dryer is composed of a main drying machine, a heater, a condenser, a cloth bag dust collector, a fan and a bin. The whole drying process is dried in a closed environment under the protection of nitrogen, and the discharge is carried out in a closed environment, with no dust and high safety.

Before use, the closed cycle boiling dryer uses nitrogen to displace the air in the system so that the oxygen content in the system reaches the safe concentration of the solvent. The wet material enters the drying machine through the feed port on the equipment in the closed container. The filtered nitrogen is fed into the blower, heated by the heater to the temperature required by the drying process, and enters the boiling bed to conduct heat and mass transfer (drying) for the material added by the differential charging port, and dries to the final humidity required by the material after the charging is completed. Closed cycle boiling dryer In the drying process, hot and humid gas with a small number of fine powder through the dust collector all the fine powder above 2um in the dust collector for gas-solid separation. The solid dust is collected in the dust collector, and the gas enters the multistage condenser (finned condenser with small pressure drop and good condensation effect) to condense the solvent in the hot and humid gas. After condensation, the solvent is collected in a collection tank and then stored (zero discharge to the air and can be recycled). The dry nitrogen after condensation and dehumidification is sent to the heater by the fan for recycling. After drying, the material on the hot air distribution board is put into the lower cylinder by the turning mechanism, and then input into the closed container through the vacuum pump or air transport system for storage and packaging (the incoming and outgoing materials are operated in the closed environment, and there is no dust in the workshop).

1、After drying by closed-loop boiling dryer, the hot and humid gas containing solvent enters the condenser and condenses the solvent in the gas (the solvent recovery rate is more than 95%), which can both recover the solvent and condense the dehumidified dry gas. The recovered solvent can be recycled again, which can save costs and will not cause exhaust emissions to the environment. After the hot and humid gas is dehumidified by condensation, the humidity in the gas is low (compared with ordinary boiling drying), the drying capacity is stronger, and it is more suitable for moisture absorbing materials that affect the humidity environment.

2、the closed cycle boiling dryer is a fully closed structure, the equipment is filled with inert gas (such as nitrogen), in the drying of anaerobic materials or materials containing flammable and explosive properties of solvent, so that there is no oxygen in the gas, can not be burned or oxidized, it can effectively avoid the equipment in the production of fire or explosion accidents, so it is safer than ordinary equipment.

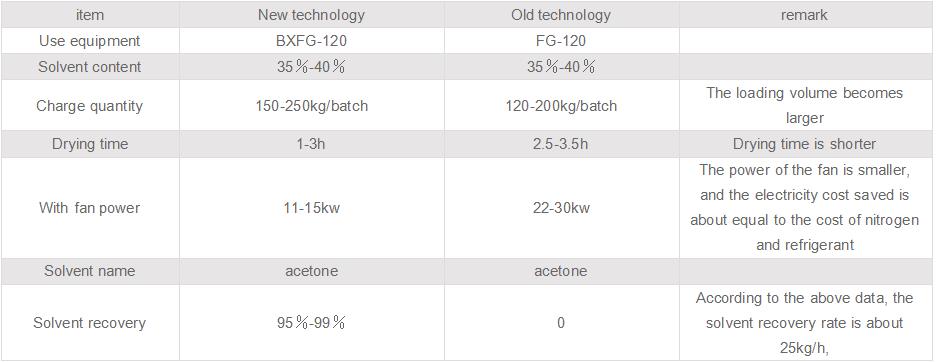

3、closed cycle boiling dryer when the internal wind required low pressure, only need micro positive pressure, so the equipment with the fan power is reduced, because in the positive pressure of the hot air is blowing from the lower part of the hopper screen, the wind penetration is strong, although the boiling height of the material is not high, but the hot air and the material contact is more full, drying rate is faster. After the fan power of the equipment is reduced, the noise of the equipment is reduced, and energy is also saved.

4、the closed cycle boiling dryer with a flap mechanism, to achieve the discharge under fully closed conditions, greatly reducing the labor intensity of workers and the operation of the workshop completely dust-free, workshop environment is good, high degree of automation.

5、the main engine of the closed cycle boiling dryer uses pulse dust removal system, high dust removal efficiency, dust does not stick to the filter cartridge, easy to disassemble and clean.

secure

Closed cycle boiling dryer is a fully closed structure, the equipment is filled with nitrogen, in the drying of anaerobic materials or materials containing flammable and explosive properties of solvent, so that there is no oxygen in the gas, can not be burned or oxidized, it can effectively avoid the equipment in the production of fire or explosion accidents, so it is safer than ordinary equipment.

The main machine of the closed-loop boiling dryer uses the bag pulse dust removal system, which has high dust removal efficiency, and the dust does not stick to the filter cartridge, which is easy to disassemble and clean. And the use of the whole machine reverse blowing technology (patented technology) in the closed cycle boiling dryer after the completion of drying the whole machine counterattack, the dust removal is thorough, the use of this technology after the equipment bag cleaning frequency from the original 1-2 days to 12-15 days a wash. The closed cycle boiling dryer is discharged at the lower part of the main engine, and can be pumped from the vacuum discharge to the material storage device to reduce the operation intensity and lift rate of workers.

After drying by the closed-loop boiling dryer, the hot and humid gas containing the solvent enters the condenser and condenses the solvent in the gas (the solvent recovery rate is more than 95%), which can both recover the solvent and condense the dehumidified dry gas. The recovered solvent can be recycled again, which can save costs and will not cause exhaust emissions to the environment.

When the closed-circuit boiling dryer works, the internal wind pressure is low, and only micro positive pressure is required, so the fan power of the equipment is reduced, because the hot air is blown upward from the lower part of the hopper net plate under positive pressure, and the wind penetration is strong. Although the boiling height of the material is not high, the contact between the hot air and the material is more full, and the drying rate is faster. After the fan power of the equipment is reduced, the noise of the equipment is reduced, and energy is also saved.

Broad spectrum

The hot and wet gas inside the closed cycle boiling dryer is dehumidified by condensation, the humidity inside the gas is low, the drying ability is stronger, and it is more suitable for the moisture absorbing materials sensitive to the humidity environment. For materials with fine particles: due to low wind pressure, the escape rate of materials is small, and all of them can be recovered in the secondary dust removal.

In the drying process, the closed cycle boiling dryer is fluidized, and the material and hot air have a large area of gas-solid contact, with high drying strength and high efficiency. With the increase of the equipment and the increase of the air volume of the equipment fan, the use efficiency of the equipment can still be guaranteed. It is not like the static vacuum drying system, with the increase of equipment, its drying efficiency is getting lower and lower. The material in the drying process of the closed cycle boiling dryer is fluidized, which avoids other undesirable conditions such as overheating and deterioration of local materials caused by direct contact between the heating surface of the material and the material in the vacuum drying system.

Previous :Closed-Loop Spray Dryer