FL series boiling pelletizing machine is also known as "one-step pelletizing machine", the use of boiling pelletizing method is the result of the comprehensive application of spray technology and fluidization technology, the use of high-speed hot air flow to fluidize powder, and then the bonding effect of atomized adhesive, so that the solid powder bridge each other, agglomeration, and gradually form particles. This machine is based on the traditional double column air cap type granulator, which is a newly developed single column airbag sealed granulator, suitable for the granulator drying operation in pharmaceutical, chemical, food and other industries.

Material powder particles, in the raw material container (fluidized bed) in a boiling fluidization state, after the purification of the heated air preheating and mixing, the adhesive solution atomized into, so that a number of particles gathered into the adhesive particles, due to the continuous drying of hot air on the material, so that the water in the particles evaporated, the adhesive solidified, this process is repeated. Formed, uniform, multi-microporous spherical particles.

1、Drug granulation and coating

Granulation: tablet granule, powder granule, capsule granule.

Coating: granule, pill protective layer, prepared color, slow release, film, enteric coating.

2、Food granulation and coating

Sugar, coffee, cocoa powder, cream, powdered juice, amino acids, flavorings, puffed food.

3、Pesticide, pigment, dye granulation

4、Powder, particle, block material drying

1. By granulation powder and improving flowability, dust flying can be reduced

2. Improve its solubility through powder granulation

3. Mixing granulation drying completed in one machine (one-step granulation method)

4. Anti static filter material is used for safe equipment operation

5. The adhesive atomizer adopts a multi fluid spray gun, with uniform mist particles and greatly improved product qualification rate

6. The equipment has no dead corners, and the loading and unloading of materials are lightweight, fast, and clean

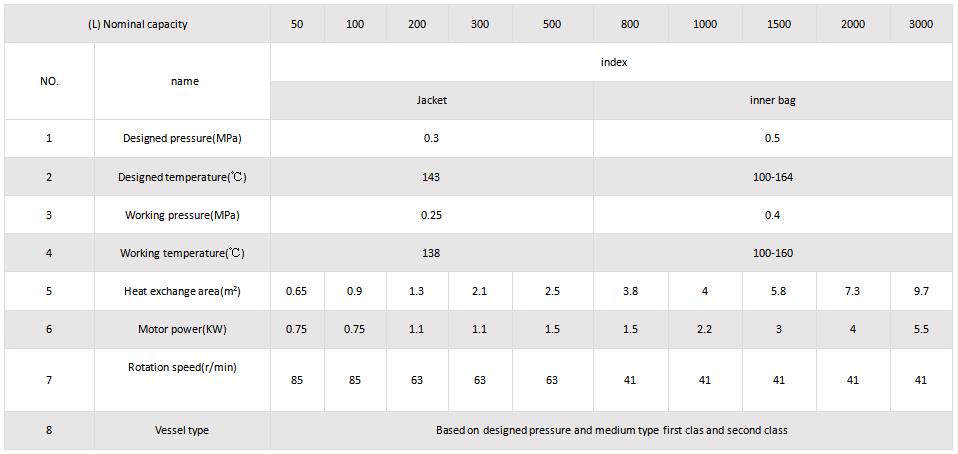

Note: The above parameters are for reference only and are subject to change without prior notice.

Previous :none!