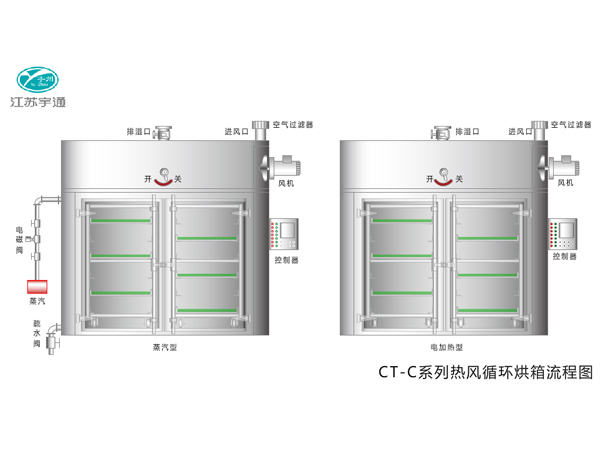

Introduction:Hot air circulation oven, after multiple upgrades and replacements, has reached the domestic and international level; The CT series is a substitute product with an average thermal efficiency of about 30%, using a centrifugal fan, external circulation of the box, and manual temperature control.

Read more

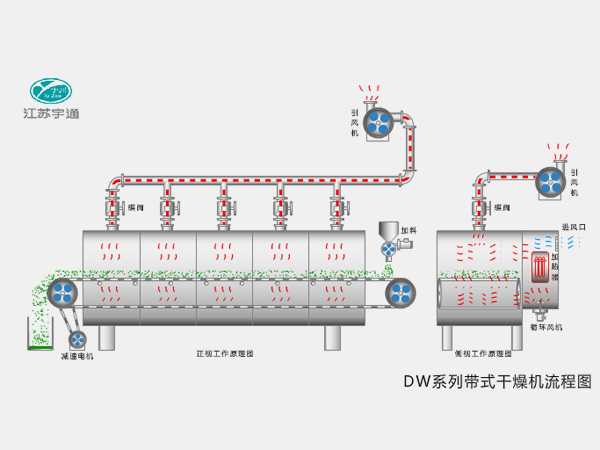

Introduction:Belt dryer is a continuous drying equipment used in batch production, used for drying sheet, strip, and granular materials with good breathability. It is particularly suitable for dehydrated vegetables, catalysts, traditional Chinese medicine decoction pieces, and other materials with high moisture content and material temperature not allowed to be high; This series of dryers has the advantages of···

Read more

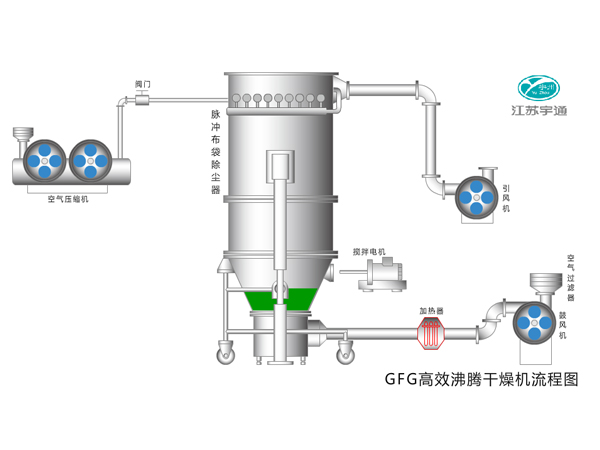

Introduction:After being heated and purified, the air is introduced from the bottom by the induced draft fan and passes through the hole plate of the hopper. In the studio, fluidization is formed through stirring and negative pressure, and the water evaporates rapidly and is carried away by the exhaust, resulting in rapid drying of the material.

Read more

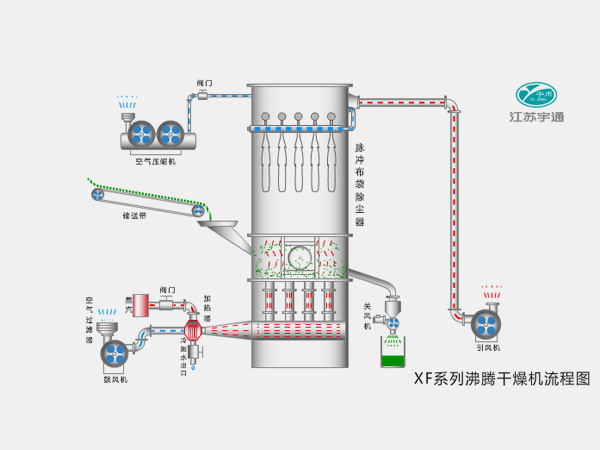

Introduction:Boiling drying, also known as fluidized bed, is composed of an air filter, heater, boiling bed host, cyclone separator, bag filter, high-pressure centrifugal fan, and control panel. Due to the different properties of the drying materials, when matching dust removal equipment, it can be considered as needed. Both cyclone separator and bag filter can be selected simultaneously, or one of them can be···

Read more

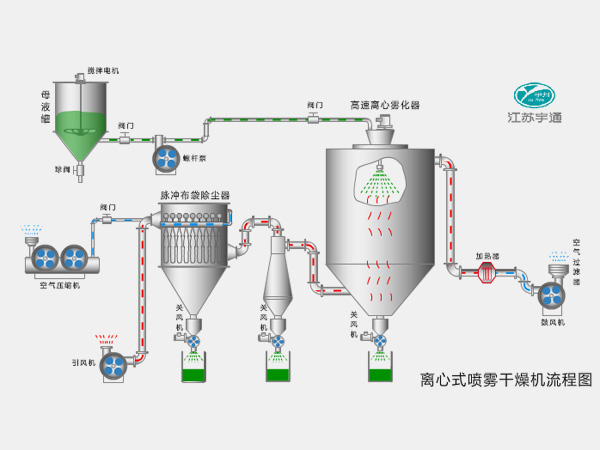

Introduction:High speed centrifugal spray dryer is widely used in liquid forming process and drying industry. It is suitable for producing powder and granular solid products from suspended lotion, solution, lotion and paste liquid raw materials. Therefore, spray dryer is a good drying process when the particle size distribution, residual moisture content, bulk density and particle shape of the finished product···

Read more

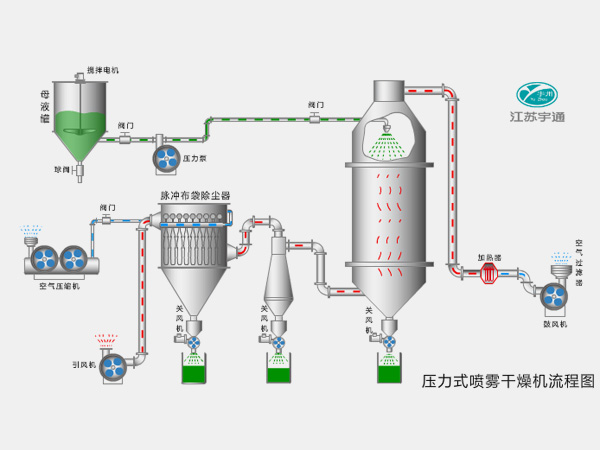

Introduction:YPG series pressure spray dryer is a device that can complete drying and granulation at the same time. According to the process requirements, the pressure, flow and nozzle size of the feed pump can be adjusted to obtain the required spherical particles in a certain proportion.

Read more

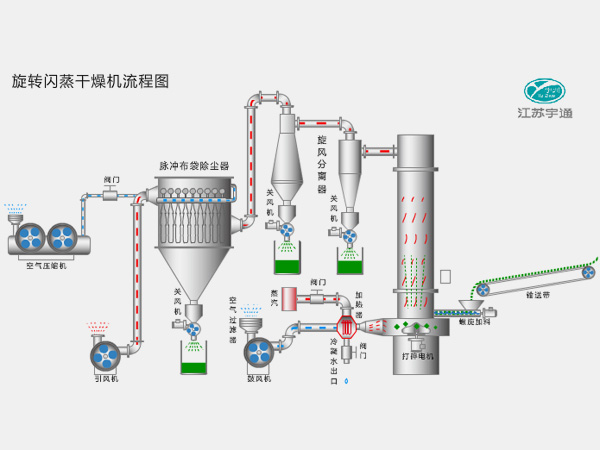

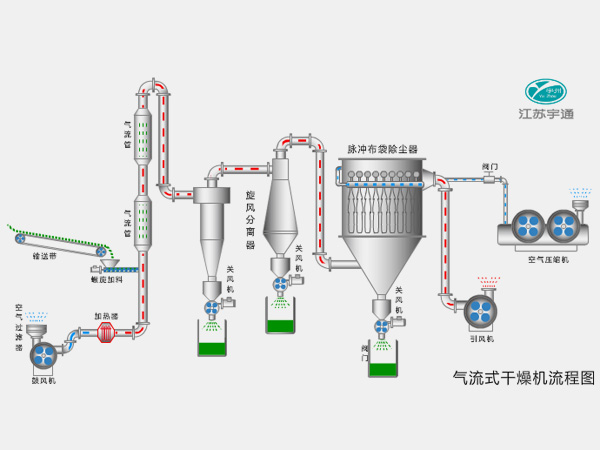

Introduction:On the basis of introducing and absorbing foreign technology, we have independently developed a new type of drying equipment. This machine has advanced technology, reasonable design, compact structure, wide applicability, high production capacity, good product quality, high efficiency and energy saving. It can dry, crush and screen in one device, eliminating environmental pollution, and achieving ···

Read more

Introduction:The bottom reinforcement device is designed with diamond shaped stirring teeth, and its streamlined performance reduces wind resistance. It is placed inside a conical hopper with a moving knife and a fixed knife, and the crushing effect is significant. The falling agglomerated material is quickly crushed into powder particles suitable for airflow drying. Another main function of stirring is to dis···

Read more

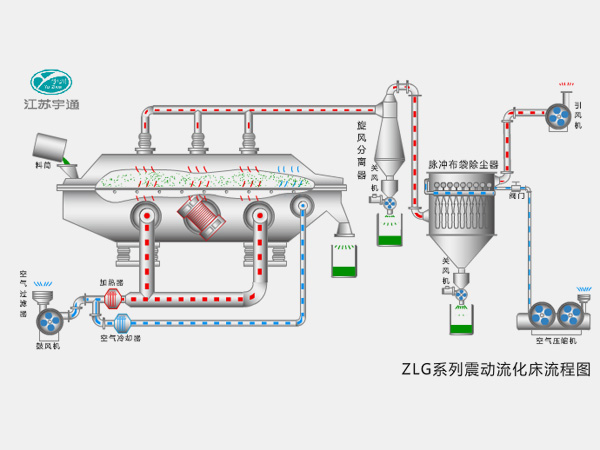

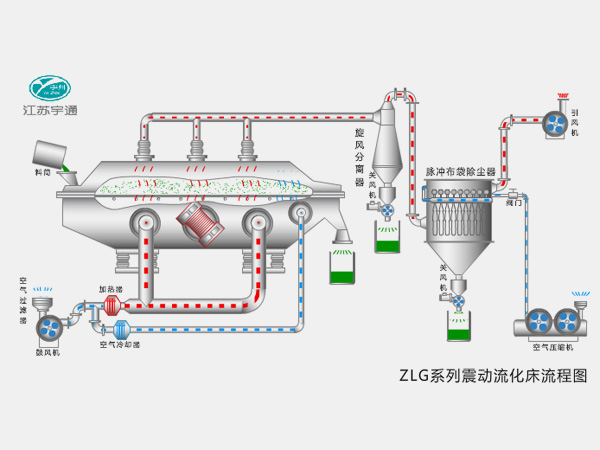

Introduction:Vibration fluidized bed is the application of mechanical vibration to the fluidized bed. Adjust the vibration parameters to achieve ideal piston flow in a regular fluidized bed with severe backmixing during continuous operation. Meanwhile, due to the introduction of vibration, the above-mentioned problems of ordinary fluidized beds will be significantly improved.

Read more

Introduction:The ZLG series vibrating fluidized bed dryer is widely used for drying, cooling, and humidifying powder and granular materials in industries such as chemical, light industry, pharmaceutical, food, plastics, grain and oil, slag, salt production, and sugar.

Read more

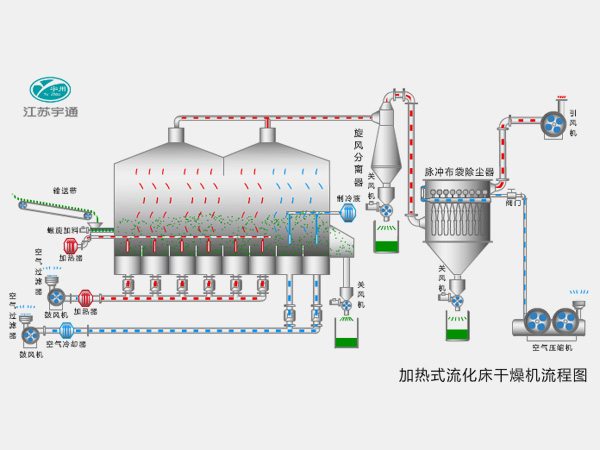

Introduction:Heated fluidized bed dryer

Read more

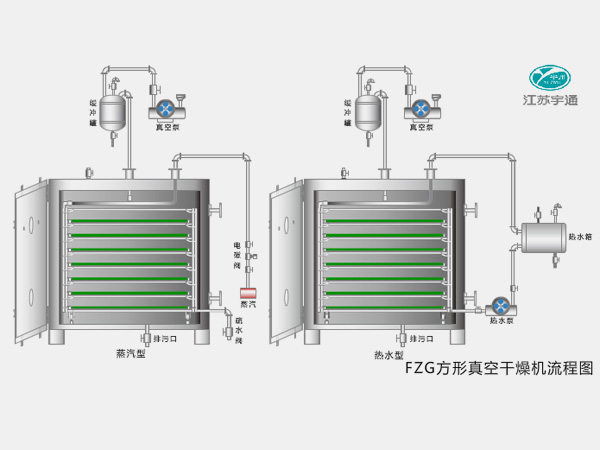

Introduction:1. The boiling point of the material solution decreases under vacuum, which increases the heat transfer driving force of the evaporator, thus saving the heat transfer area of the evaporator for a certain amount of heat transfer. 2. The heat source for evaporation operation can be low-pressure steam or waste heat steam. 3. The evaporator has less heat loss and can achieve a higher drying rate at lo···

Read more