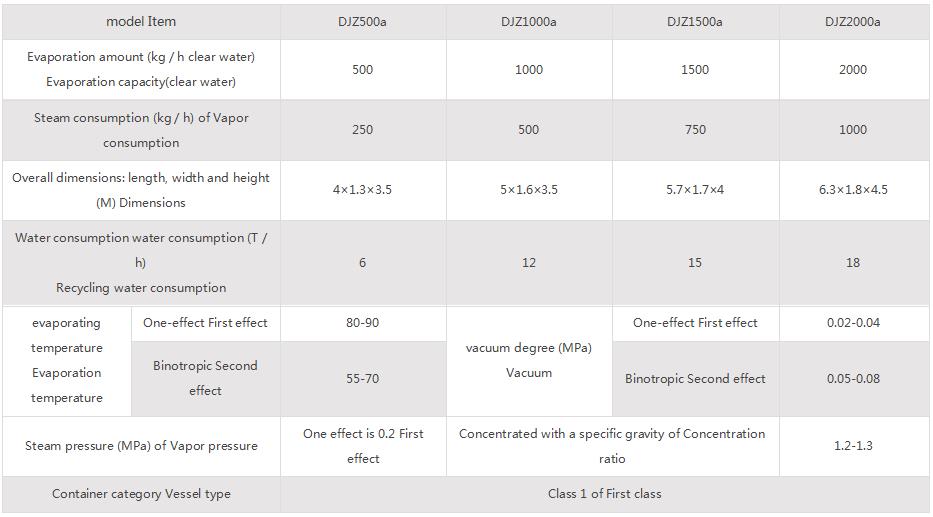

This equipment is suitable for low-temperature vacuum concentration of thermosensitive materials such as traditional Chinese medicine, western medicine, glucose, brewing and sprinkling, starch, oral liquid, chemical industry, food, monosodium glutamate, dairy products, etc. Users can choose the series of concentrators in the technical parameters based on the concentration amount.

1, energy efficiency, according to the WZ1000 calculation, a year to save 3,500 tons of steam, save 90,000 tons of water, save 80,000 degrees of electricity, discount RMB 100,000-150,000.(with the same specifications of the single effect comparison)

2, the concentrator adopts two-effect evaporation at the same time, and the secondary steam is fully utilized, which not only saves the investment of the boiler, but also saves energy consumption, and the energy consumption is reduced by 50% compared with the single-effect concentrator.

3, the equipment adopts external heating natural circulation and vacuum negative pressure evaporation, evaporation speed is fast, concentration ratio is significant. The liquid material has no foam concentration in the full seal, and the medicine liquid concentrated by the equipment has no pollution and strong medicine taste. Easy to clean (open the top cover of the heater)

4, the equipment and liquid material contact parts are made of (OCr18Ni9) stainless steel, in line with GMP standards. Heater, evaporator, plus thermal insulation, thermal insulation outer layer with patterned stainless steel sheet, the equipment in the workshop appears more luxurious and beautiful.