YPG series pressure type spray dryer is a device that can complete drying and granulation at the same time. According to the process requirements, the pressure, flow and nozzle size of the feed pump can be adjusted to obtain the required spherical particles with a certain size ratio.

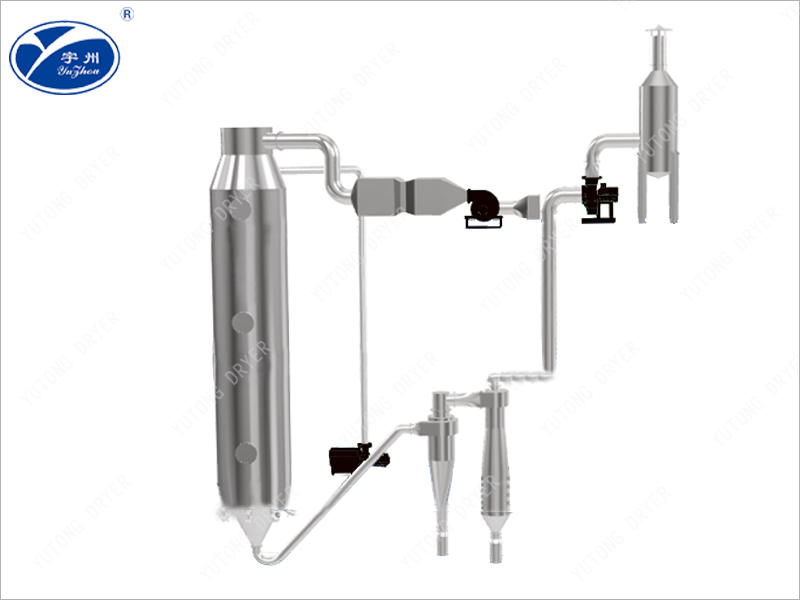

The air enters the heater through the filter, is exchanged into hot air, and enters the hot air distributor on the top of the drying chamber, so that the air uniformly enters the drying chamber in a rotating shape or parallel axis. The material liquid needs to be sieved and pumped by high pressure to the nozzle located at the top center of the drying chamber to atomize the material liquid evenly, so that the surface area of the droplet is greatly increased, and the contact with the hot air causes the water to evaporate rapidly and dry into granular products in a very short time. Most of the products are collected by the discharge port located at the bottom of the tower, and the waste gas and small powder particles are separated by the rotary wind separator. The finished product is collected by the collection cylinder at the lower end of the cyclone separator, and the exhaust gas is discharged by the extraction fan.

Equipment process demonstration

1, the drying speed is fast, the surface area of the material liquid is greatly increased after atomization, in the hot air flow, 95% to 98% of the water can be evaporated instantly, the drying time only takes ten seconds to tens of seconds, especially suitable for the drying of heat-sensitive materials.

2, the product is spherical particles, uniform particle size, good fluidity, good solubility, high product purity, good quality.

3, wide range of use, according to the characteristics of the material, you can use hot air drying, you can also use cold air granulation, strong adaptability to the material.

4, simple and stable operation, convenient control, easy to achieve automated operations.

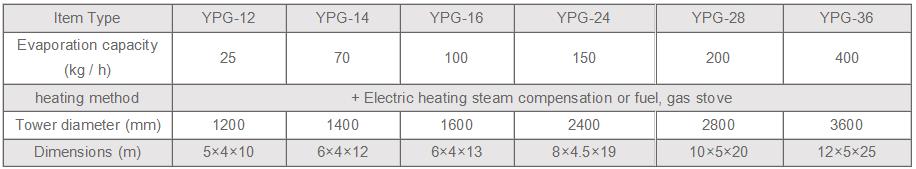

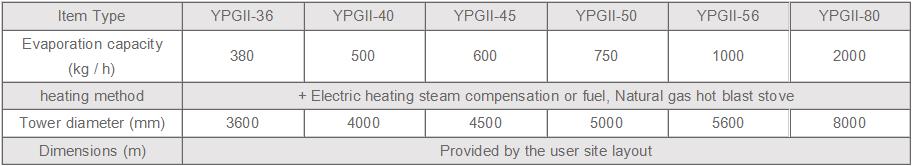

Note: 1, the amount of water evaporation is related to the characteristics of the material and the evaporation temperature, and the inlet air temperature is calculated at 150~160℃ in this table. 2, the user can choose downstream, reverse mixing, return powder and other drying methods, in order to achieve the required product effect. 3, the process diagram is only for schematic, please choose the components according to needs.

Applicable material

Spray drying or granulation of food, medicine, chemical, dyeing, ceramics, biochemistry, pesticides, plastics and other materials with good fluidity.

1. Chemical industry: catalysts, resins, synthetic laundry powders, oils, ammonium sulfide, dyes, dye intermediates, white carbon black, graphite, ammonium phosphate, etc.

2. Food: amino acids and analogues, seasonings, proteins, starches, dairy products, extracts, fish meal, meat essence, etc.

3, Pharmaceutical: proprietary Chinese medicine, pesticides, antibiotics, Chinese medicine powder, etc.

4, ceramics: magnesium oxide, China clay, various metal oxides, dolomite and so on.

5, spray granulation: all kinds of fertilizer, alumina, ceramic powder, pharmaceutical, heavy metal superhard steel, fertilizer, granular washing powder, Chinese patent medicine.

6, spray cooling granulation: amine fatty acids, paraffin, glycerate, tallow, etc. Spray crystallization, spray concentration, spray reaction and so on are often used.