ZPG series Chinese medicine extract spray dryer is a drying equipment for Chinese medicine products with low melting point and high sugar content developed by absorbing foreign technology, and has the characteristics of non-sticking wall, non-coking material, and not easy moisture absorption. The device determines the process conditions of spray drying according to the characteristics and properties of drying products, has a high degree of automation, easy operation and meets the requirements of GMP. The successful development of the device has solved the technical difficulties that many traditional Chinese medicine products with low melting point and high sugar content cannot be spray dried for many years, and is also a new development of the application technology research of spray drying in traditional Chinese medicine.

ZPG series Chinese medicine extract spray dryer is the application of centrifugal spray drying technology in the drying of specific materials. The drying equipment is specially used to solve the spray dryer of Chinese medicine extract and plant extract. It effectively solves the problems of wall sticking, coking, low powder yield and low yield of the original LPG series high-speed spray dryer in the drying of Chinese medicine extract.

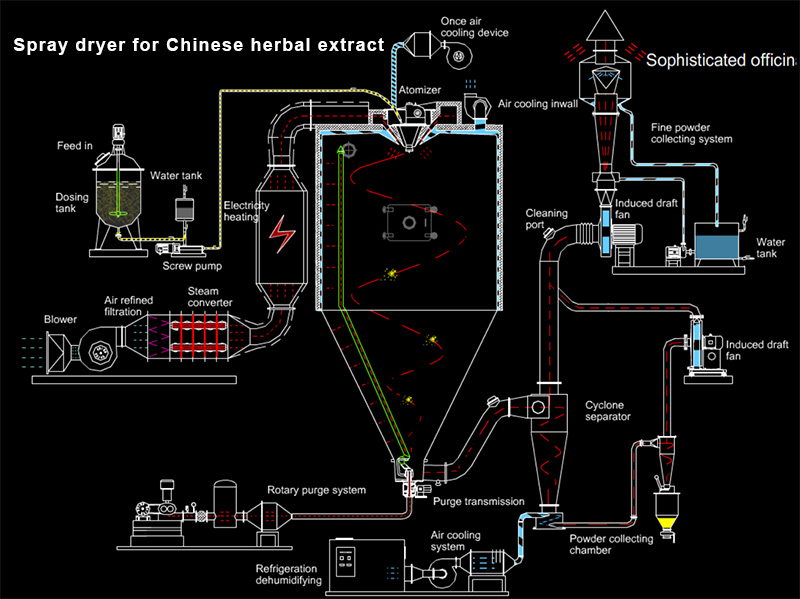

The air enters the air heater after the air filter, when the air heater to the given temperature in the tangent direction into the hot air distributor, the air after the action of the hot air distributor, uniform, spiral into the drying chamber, while the material liquid atomized by the atomizer into 20~60um droplets, when the droplets contact with the hot air quickly vaporized and dried into powder or particle products. After the cyclone separator is used to collect the material directly, it is conveyed to the silo by the air to complete the cooling and conveying of the material. The exhaust gas is discharged by the fan outlet through the water dust collector.

1. The tower body has a cold air jacket;

2, the tower body is equipped with automatic vibration device;

3. The tower body and pipeline are equipped with quick-opening cleaning holes and blowdown holes;

4, automatic control of constant temperature feeding tank;

5, manual high pressure washing tower with accessories;

6, the part in contact with the material is made of stainless steel material;

7, material collection using two-stage cyclone dust removal device, or wet dust collector;

8, air intake temperature to achieve automatic control.

9, equipped with gas sweep device.

Note :

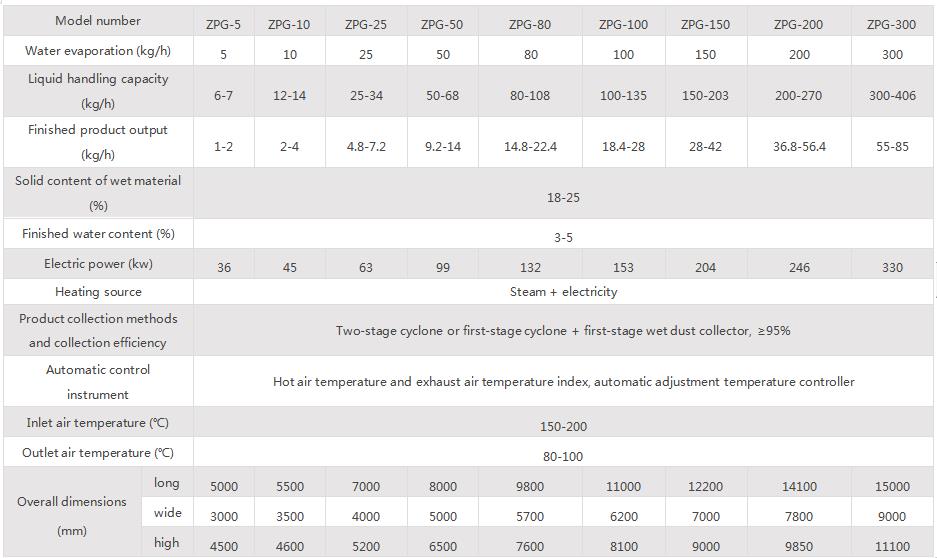

1, the actual dimensions can be determined according to the actual situation of customers, the above dimensions are for reference only;

2, the above evaporation is Z maximum evaporation.