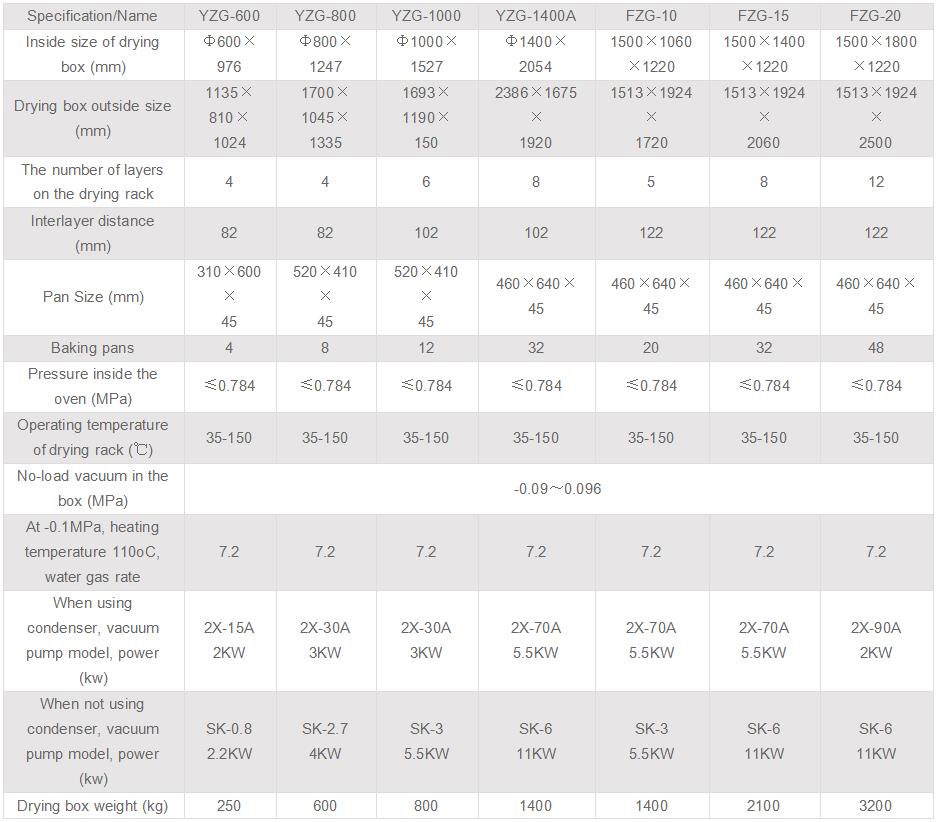

The YZG/FZG series vacuum dryer belongs to the static vacuum dryer. This drying equipment heats the dried material under vacuum conditions and uses a vacuum pump to extract air and moisture, keeping the working chamber in a vacuum state. This greatly accelerates the drying rate of the material and saves energy. If a condenser is used, the solvent in the material can be recovered through the condenser. If the solvent is water, the condenser can be omitted, saving energy investment.

1. The boiling point of the material solution decreases under vacuum, which increases the heat transfer driving force of the evaporator, thus saving the heat transfer area of the evaporator for a certain amount of heat transfer.

2. The heat source for evaporation operation can be low-pressure steam or waste heat steam.

3. The evaporator has less heat loss and can achieve a higher drying rate at lower temperatures, fully utilizing heat.

4. Can dry unstable or heat sensitive materials at low temperatures, as well as materials containing solvents and requiring solvent recovery.

5, can be disinfected before drying, drying process without foreign bodies mixed, in line with GMP requirements.

6. It belongs to a static vacuum dryer, so the shape of the dried material will not be damaged.

7. Using a condenser can effectively recover solvents from materials.

Suitable for low-temperature drying of thermosensitive materials that are prone to decomposition, polymerization, and deterioration at high temperatures, it is widely used in industries such as pharmaceuticals, chemicals, food, and electronics.

The above data. For reference only. If there are special requirements, our factory provides design and consulting services.