GXG series filter elution drying machine has good adaptability to all kinds of materials, especially suitable for the treatment of slurry that is difficult to filter and flammable and explosive, volatile, and easy to pollute materials. This equipment integrates filtration, beating, washing and drying, and is an ideal equipment for solid-liquid separation in pharmaceutical, pesticide, food, chemical, dye and other industrial sectors.

This machine is independently designed, developed and produced by our company, and put into practical application, filling the domestic blank of this kind of products, and has been widely used in the separation of many harmful and polluted materials.

GXG series filter elution drying machine is mainly composed of transmission parts, lifting parts, washing parts, scraper mechanism, barrel assembly, pneumatic device, filter disc, frame and related pipes and testing control instruments and other main components.

1, transmission parts:

The transmission parts are mainly composed of motor, reducer, drive shaft, bearing seat, lubrication system, seal and so on. The motor reducer drives the drive shaft and the scraper mechanism on the shaft to achieve the positive and reverse, through the positive and reverse of the scraper mechanism to remove the filter cake, crush the filter cake crack caused by pressure leakage, and also plays the role of mixing and mixing for the materials that need to be pulped and washed. The seal ensures that there is no leakage between the cylinder and the drive shaft and ensures the internal pressure of the cylinder.

2, lifting parts:

The lifting part is mainly composed of the cylinder, the guiding mechanism, etc., which is the executive mechanism to ensure the up and down movement of the scraper. The accurate reliability of the position of the lifting parts is crucial, therefore, in the installation, commissioning, operation and maintenance process, it is necessary to carefully ensure the adjusted position of the stroke switch to ensure the accurate operation of the lifting parts, so as not to cause the scraper to damage the filter disc and other serious consequences because of its wrong position.

3, washing parts:

The washing unit realizes the washing of the inside of the cylinder and the filter cake. The washing liquid enters from the inlet of the washing tube through a number of washing nozzles to achieve multiple, all-round, continuous and uniform washing of the inside of the cylinder and the filter cake.

4, upper cylinder:

The upper cylinder is composed of a cylinder, a head assembly, a flange, etc. The head assembly includes a head, breathing valve, safety valve, pressure gauge, sight mirror, washing liquid inlet, feed port, compressed air inlet and other inlet nozzle. The transmission parts, lifting parts and washing parts are installed on the upper cylinder.

5, scraper mechanism:

(1) Discharge: After the filter is finished, the filter cake is formed on the filter disc, and the scraper mechanism is lowered and rotated, and the filter cake is scraped up and discharged out of the machine at the discharge valve; (2) Grinding: When the filter cake cracks, the scraper device turns in reverse to grind the cracks flat to avoid pressure leakage to ensure the normal filtration; (3) Mixing: For the materials that need to be repulped and filtered, it can play the role of mixing, accelerate the replacement of the washing liquid and the mother liquid, and optimize the washing effect.

6, discharge valve:

Adopt manual or automatic quick-opening discharge valve. Mounted on one side of the cylinder, the cake is discharged from its valve port.

7, filter plate:

It is composed of multi-layer metal sintered mesh. It can be divided into integral installation type and split installation type. The integral mounted filter disc is one unit. The separate mounted filter disc is divided into several pieces, and each small filter disc is installed independently. Filter precision and material can be selected according to actual needs. The filter disc has good rigidity, accurate filtration accuracy, and can be repeatedly washed and used for a long time. The filter disc is the key part of the whole machine, and its precision is directly related to the filtering effect.

8, lower cylinder:

The lower cylinder is the carrier for mounting the filter disc. It is composed of flange, cylinder, head, discharge valve port, liquid outlet, movable support frame, etc. The lower cylinder can be automatically lifted to the ground under the action of the cylinder, and the movable support frame can be quickly and easily moved to facilitate the thorough cleaning of the filter disc.

9, rack:

The frame is the support of the whole machine. The support legs of the rack have anchor bolt holes.

10, automatic control system:

The control of the machine through PLC or computer centralized control, through the pressure controller, temperature controller, stroke switch, proximity switch and material level detector monitoring and feedback, so as to achieve automatic control.

The working process of GXG series filter elution drying machine can be divided into four processes:

(1) Feed filtration: Under the action of the pump, the material to be separated enters the machine and starts the initial filtration through the pressure action of the pump. After the end of feeding, compressed gas is passed through, and under the pressure of compressed air, it is filtered again to realize the solid-liquid separation of the material to be separated. Filter media can be selected according to different products and material characteristics, various specifications and different media of the filter cloth or stainless steel multi-layer sintered filter disc, filtration accuracy can reach 5-10μm, the filter disc is fixed on the lower cylinder of the machine, can be cleaned and disassembled. Replacement of product varieties, only need to replace the filter plate can be achieved, one device can be used for multiple products. The formed filter cake is smoothed by a special scraper mechanism to eliminate the cracks of the filter cake, so that the filter cake is evenly distributed and the thickness is consistent, so that the solid-liquid separation is more thorough.

(2) beater washing: Through the special washing mechanism, the cleaning liquid can be comprehensively and evenly distributed in the machine, which can realize the internal cleaning and material washing of the machine. The filter cake and washing liquid can be fully mixed layer by layer through the stirring and mixing function of the scraper mechanism, and finally the slurry suspension is formed, and the filter cake is fully washed. According to the specific conditions of the material, you can choose to wash several times.

(3) Blow drying: After full washing, the compressed air is passed into the filter cake to blow dry. For materials that need to be dried, steam or hot air (nitrogen) is passed in to dry the material under the action of vacuum.

(4) Discharge: Under the action of the scraper mechanism, the blown cake is scraped up and driven to the side discharge valve position and discharged out of the machine.

1, multi-service, including filtration, elution and drying function;

2, in a closed environment operation, especially suitable for harmful substances, need to avoid pollution of materials.

3, can use PLC control, high degree of automation

4, filter double layer net to ensure that the material does not leak.

5, compact structure, easy to install, operate and maintain, occupy a place.

6, no vibration and noise, stable and reliable operation.

7, the equipment can be made with all stainless steel, easy to clean, fully determine the GMP standard.

1. Pharmaceutical industry.

2. Fine chemical industry.

3. Dye and pigment industry.

4. Food industry.

5. Chemicals extracted from agricultural products.

6. Polymer and resin products.

7, the equipment can be made with all stainless steel, easy to clean, fully determine the GMP standard.

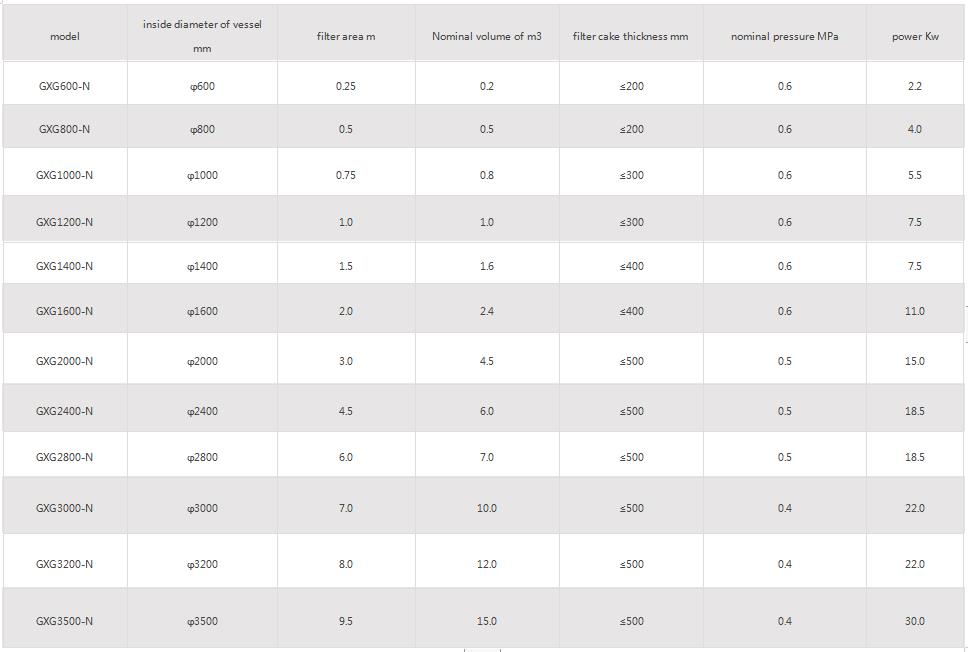

Note: Different filtration accuracy, machine material, structure configuration can be selected according to the specific material.

Previous :FZG \ YZG series vacuum dryer