This device uses efficient ceramic corrugated packing. The distillation tower body is made of stainless steel, which prevents the phenomenon of iron filings blocking the packing and extends the service life of the device. All parts of the equipment in this device that come into contact with alcohol, such as condensers, stabilizing tanks, cooling coils, etc., are made of stainless steel to ensure that the finished alcohol is not contaminated. The W-shaped distillation kettle adopts a detachable U-shaped heating tube. During maintenance, the U-shaped heating tube can be removed from the outside of the kettle for easy cleaning of the outer wall of the heating tube and the inner wall of the distillation kettle.

ZW type eliminates the need for indirect heating distillation vessels. The condenser adopts a tube type heat exchanger, and spiral plate heat exchangers can also be supplied according to user requirements. The cooler adopts a coil type cooler, which is equipped with a stabilizing tank and a specific gravity analyzer.

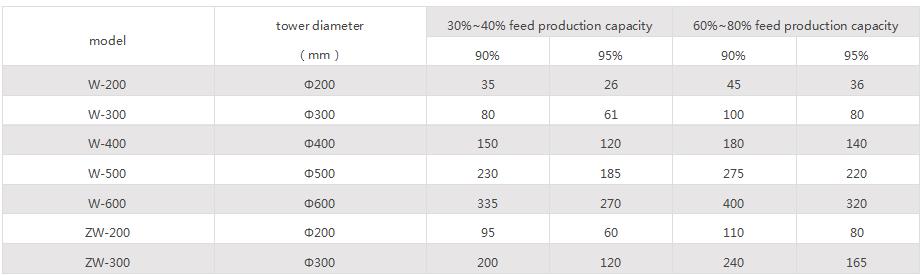

This device is suitable for the recovery of dilute alcohol in industries such as pharmaceuticals, food, light industry, and chemical engineering. It is also applicable to the distillation of other solvents such as methanol. This device can distill dilute alcohol at around 30 ° C to 90-95 ° C alcohol according to user requirements. If the alcohol content of the finished product is required to be high, the reflux ratio can be increased, but the yield will correspondingly decrease.

The W-type is available in five specifications, each of which includes a corresponding configuration of a distillation tower, still, condenser, cooler, pressure regulator, and specific gravity meter. Among them, W-200 and W-300 distillation towers are directly installed on the still. W-400, W-500, W-600 distillation column and distillation tank are installed respectively.

ZW type has ZW-200, ZW-300 two specifications, each specification includes the corresponding preheater, distillation tower, condenser, cooler, pressure regulator, specific gravity meter.

Other auxiliary equipment and instruments such as: measuring tank, storage tank, conveying pump, rotameter, temperature indicator and so on, our factory can also be processed according to user requirements or ordered on behalf of the supply.

1、Feed concentration: 30% ~ 80%

2、Discharge concentration: 90% ~ 95%

3、Reflux ratio: R=13 (depending on the concentration of incoming and outgoing materials)

4、Alcohol concentration of residual liquid discharge: W type ≤3%, ZW≤1%

5、Production capacity (kg/h): See the table below