Baking tray, also known as a tray or baking pan, refers to a utensil used to hold materials in a drying oven, usually made of metal. In industrial production, drying trays are generally not used separately and are equipped in drying boxes, vacuum ovens, and other equipment to work together. At present, baking discs widely used in industries such as pharmaceuticals, chemicals, food, and agricultural products are mainly divided into two categories based on the materials used: stainless steel and aluminum alloy (with a small amount of iron baking discs used for enamel coating on the outer wall); According to their different shapes, they can be divided into non perforated disks and perforated disks; According to different processing methods, it mainly consists of handmade plates and one-time molding and pressing drying plates.

1. There are two forms of baking plate: rolled edge plate and straight edge plate (also known as GMP baking plate).

2, specification: 460×640×45mm.

3, material: stainless steel, aluminum alloy, Teflon coating, enamel, polypropylene (plastic), etc.

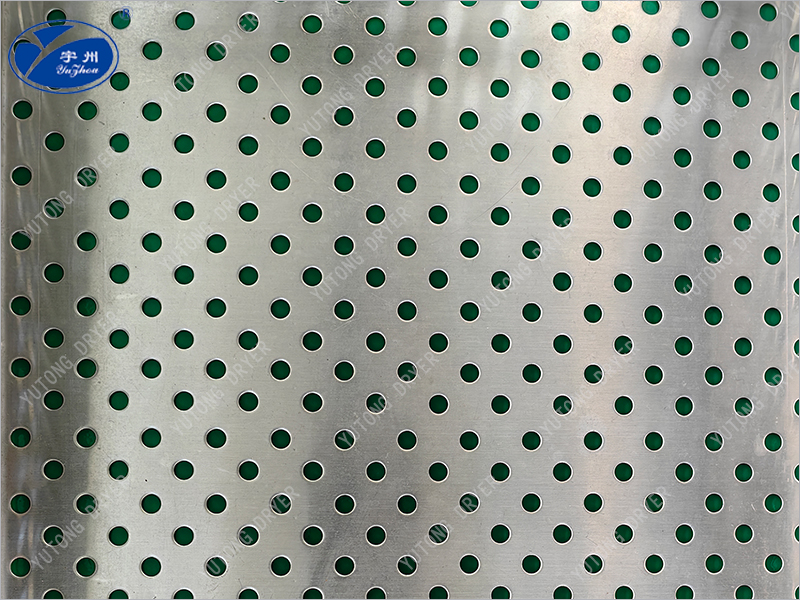

4, in order to increase the air permeability, we can customize all kinds of punching and drying tray, tic-tac-toe net tray, pressing tray or incoming material processing. Welcome to call!

5, a molding pressed edge baking tray is specially for hot air circulation oven supporting products, standard size: 640×460×45mm, conventional plate thickness 0.5mm, can also be made according to user requirements non-standard, the material is aluminum alloy, stainless steel, PTFE coating, enamel, polypropylene.

6, the standard plate dimensions: 640*460*45mm, for a die stamping molding, drying plate conventional thickness 0.5mm, as well as thickening 0.6mm, 0.7mm, 0.8mm, 0.9mm, 1.0mm. In addition, in order to increase the air permeability can be punched, the aperture 1-10mm for the user to choose, the production process has rolled edge disk, straight side disk, the new version of GMP rolled straight edge.

7, no hole disk: poor permeability, suitable for powder, liquid materials;

8, punching disk: permeability is general, suitable for granular materials;

9, manual well plate: good permeability, suitable for strip, sheet materials and loose materials.

10, our pressing standard punching disk, size 640*460*45, can contact customer service required aperture size, the company supply, large quantity more preferential.

11, the customer needs to communicate the parameters when ordering: plate thickness, load-bearing requirements, material, whether to punch holes, (if it is a net disk, please confirm the diameter of the mesh), quantity and delivery date, what characteristics of the material loaded, powder, granular material, block material, or liquid material, whether corrosive;

12, the general standard drying tray has more than 1000 inventory, the quantity is not much can be shipped on the same day, the price of drying tray will fluctuate with the fluctuation of materials and up and down deviation, large quantity can be discounted, subject to the actual inquiry!

13, in the above baking tray, and a molding pressing baking tray is common, the size is 640×460×45mm, mainly made of stainless steel or aluminum alloy through a molding pressing, its corners are smooth, around the edge, to ensure that the cleaning is thorough, and easy to support the advantages, so widely used in production.

1, the standard disk dimensions are: 640*460*45mm, a stamping molding for the mold, the arc is excessive without dead Angle, the four sides of the rolling process, to avoid scratching the hand, the thickness of 0.5mm,0.6mm, 0.7mm, 0.8, 0.9, 1.0mm thick options, the production process has a straight edge, rolling edge, GMP rolling straight edge. The overall size is limited by the mold size and cannot be changed.

2, the bottom of the standard drying pan can be punched: the advantages of good permeability, the diameter of the hole is: Φ1.0-Φ10.0mm optional, the side can not be punched, affecting the structural strength;

3, stainless steel mesh plate: the structure is four sides of stainless steel plate folding, the bottom edge of stainless steel braided mesh and lined with well reinforcement, good permeability, can be customized according to customer size of any size;

4, non-standard custom stainless steel manual plate: according to customer size requirements to customize the drying plate, the structure is stainless steel plate cut and folded after four sides welding, the bottom can be punched, the advantage is that any size can be customized to meet customer needs;

5, GMP baking tray: is a supporting product for pharmaceutical oven, (also known as a molding pressing straight edge plate, no dead Angle), can be thoroughly cleaned. Standard size 640×460×45mm;

6, drying equipment accessories: once formed stainless steel drying tray, stainless steel drying tray, aluminum alloy drying tray, punching tray, all kinds of manual tray, steam tray, clamshell tray, socket tray, radiator, seal strip, blade, door lock hinge, radiator, all kinds of fans;

1. One molding pressed edge baking tray is specially designed for hot air circulation oven supporting products, standard size: 640×460×45mm, can also be made according to user requirements non-standard, the material is aluminum alloy, stainless steel, Teflon coated tray.

2.GMP baking tray is a supporting product for pharmaceutical GMP oven, (also known as a molding pressing straight edge tray), can be thoroughly cleaned. Standard size 640×460×45mm.

3. Axial fan is oven supporting products, power 0.45Kw, materials are aluminum alloy, stainless steel, carbon steel. Can also be non-standard production.

4. The radiator is a matching product of the oven, and the material is carbon steel, aluminum alloy, stainless steel fins. Can also be non-standard production.

5. The dryer and the wheel of the dryer are auxiliary products of the oven. The material is carbon steel and stainless steel. Can also be non-standard production.

6. Door lock hinges are oven supporting products, materials are carbon steel, stainless steel.

1, the socket plate is dedicated to the drying and transfer of bottles, customers can provide any length, width and height of the meaning of size customization, handmade sheet metal made, the plate and the side socket can be separated, easy to load and unload bottles.

2, the bottom and four sides can be punched according to customer needs, punching diameter 3-10mm, plate thickness can be customized.

3, the material standard is SUS304, and 316,321,310 and other stainless steel options.

Previous :Alcohol recovery tower