Anshan in Liaoning Province

Mesophase carbon microspheres are micron-level spherical carbon materials formed from anisotropic mesophase microspheres formed by thermal condensation polymerization during heat treatment of asphaltic compounds and separated from the asphalt matrix. It is mainly used in lithium ion battery anode materials, composite materials, activated carbon microspheres and other industries.

The intermediate phase carbon microsphere material contains washing oil moisture, the specific gravity is about 600kg/m& sup3; , loose fine powder. The washing oil content before drying is about 35% to 40%, and the washing oil content after drying is about 0.5%. Boiling point of washing oil 230℃~260℃.

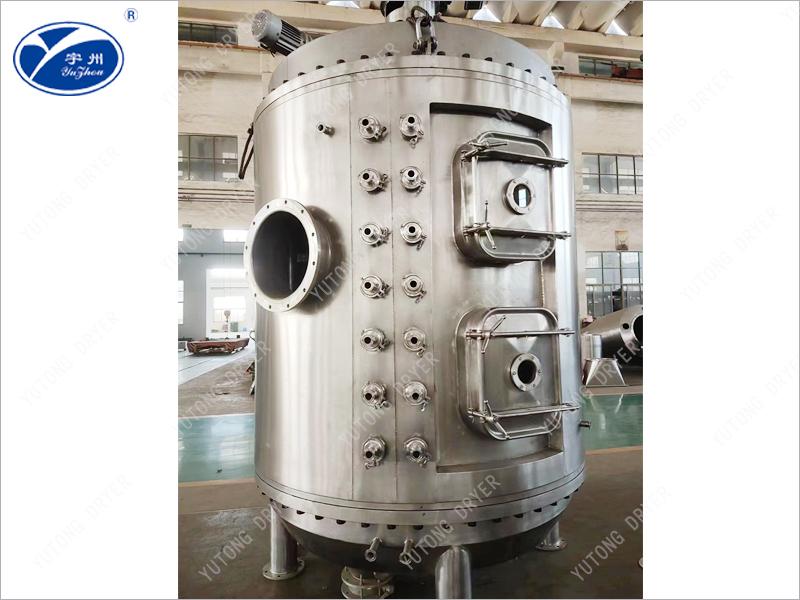

Closed disc continuous dryer is in the atmospheric pressure disc continuous dryer on the basis of closed treatment, so more suitable for the need to recover solvents, materials easy oxidation, material odor is heavy occasions, it has: continuous operation, closed operation, evaporation strength, humidity gradient distribution reasonable, low power consumption, small footprint, environmental protection and other advantages. At the same time, its configuration is simple, does not use hot air as the heating medium, so there will be no product loss caused by bad separation of hot air and dust with tail gas entrainment. The disc continuous dryer is composed of a drying disc, a rake arm, a number of rake blades installed on the rake arm, roller, a spindle, a transmission device, a shell, etc., and a heating medium is passed into the hollow drying disc. The material is transported by the rake leaf on the surface of the drying disc, turned, and moved in the Archimedes spiral track. During the movement, the drying disc is heated, heat and mass transfer is carried out to complete the drying operation. According to the yield, nature, initial and final moisture content of the drying disc, the number of drying disc layers (drying area) is determined. The disc continuous dryer works vertically. The wet material is added by the feeding port at the top and discharged from the bottom of the dryer after passing through the drying pan of each layer. The moisture released from the material is discharged into the atmosphere by the induced draft fan after dust removal.