Introduction:This equipment is widely used in the pharmaceutical industry, biotechnology and other fields. It is a vacuum box drying device that complies with the new version of GMP. It is mainly aimed at drying thermosensitive materials, viscous materials, and materials that require solvent recovery. Especially for materials with high pond content, easy overflow, and easy foaming of traditional Chinese medici···

Read more

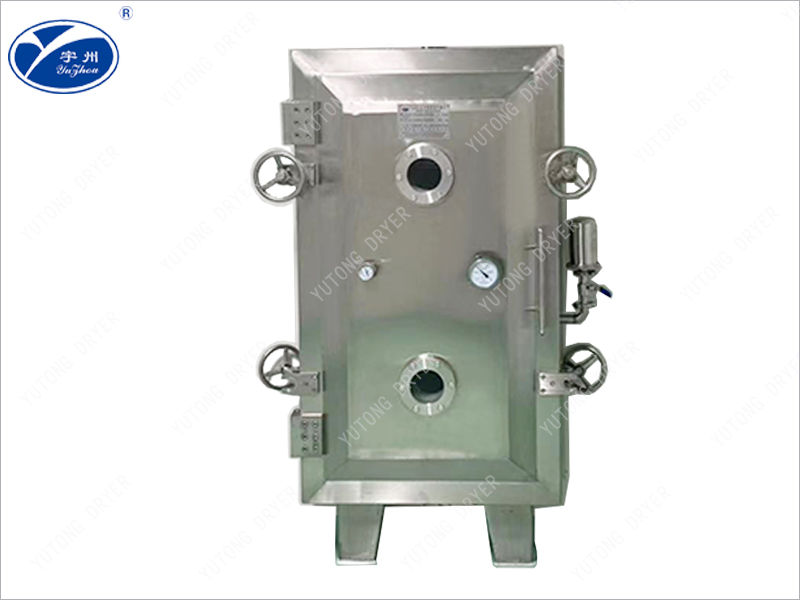

Introduction:The YZG/FZG series vacuum dryer belongs to the static vacuum dryer. This drying equipment heats the dried material under vacuum conditions and uses a vacuum pump to extract air and moisture, keeping the working chamber in a vacuum state. This greatly accelerates the drying rate of the material and saves energy. If a condenser is used, the solvent in the material can be recovered through the conden···

Read more

Introduction:This machine is a new type of horizontal intermittent vacuum drying equipment, wet materials through conduction evaporation, with a scraper agitator constantly remove the material on the inner wall, and push in the container to form a circulation flow, water evaporation by the vacuum pump out.

Read more

Introduction:The SZG double cone vacuum dryer is a new generation drying device developed by our factory in combination with similar domestic product technology. The double cone vacuum adopts a belt chain elastic connection method, so the equipment runs smoothly. The specially designed process fully reflects the good concentricity of the two shafts, and reliable mechanical seals or American technology rotary j···

Read more

Introduction:Single cone vacuum dryer is an efficient and multifunctional fully enclosed vertical vacuum drying equipment that integrates drying, crushing, and powder mixing. Its drying efficiency is 3-5 times that of the same specification "double cone rotary vacuum dryer". Mainly used for powder drying in industries such as pharmaceuticals, chemicals, pesticides, and food, it can achieve continuous operation···

Read more

Introduction:The DZG sterile single arm double cone rotary vacuum dryer is suitable for low-temperature drying of powdered, granular, and fibrous materials (such as biochemical products) in industries such as chemical, pharmaceutical, and food. It is also more suitable for drying materials that are prone to oxidation, volatilization, heat sensitivity, strong irritation, toxicity, and materials with special req···

Read more

Introduction:The GXG series filtration, washing, and drying all-in-one machine has good adaptability to various materials, especially suitable for processing difficult to filter slurries, as well as flammable, explosive, volatile, and easily contaminated materials. This equipment integrates filtration, pulping, washing, and drying operations, making it an ideal device for solid-liquid separation in industrial ···

Read more

Introduction:The LZG series spiral vibration dryer is mainly suitable for drying traditional Chinese medicine pills, as well as for drying granular, short strip, and spherical materials in industries such as chemical, pharmaceutical, food, plastic, building materials, and feed.

Read more

Introduction:This product can indirectly heat or cool paste, granular, powdered, and slurry materials, and can complete unit operations such as drying, cooling, heating, sterilization, reaction, and low-temperature combustion. The special wedge-shaped stirring heat transfer blade in the equipment has high heat transfer efficiency and self-cleaning function of the heat transfer surface.

Read more

Introduction:The drum scraper dryer is an internal heating and conduction type rotary drying equipment. Wet materials obtain heat transferred through thermal conduction on the outer wall of the drum, removing moisture to achieve the required moisture content. The heat is transferred from the inner wall of the cylinder to the outer wall, and then passes through the material film. It has high thermal efficiency ···

Read more

Introduction:After being fed into one end of the dryer, the wet material is evenly distributed and dispersed inside the dryer by flipping the plate reader evenly distributed in the inner cylinder. It also comes into full contact with the hot air flowing in parallel (counter current), accelerating the driving force of drying and mass transfer. During the drying process, the material can be controlled to move to···

Read more

Introduction:The GZG tube bundle dryer is an indirect heating contact dryer that can be used for both downstream and upstream drying. It is currently one of the widely used and advanced drying machines in most countries.

Read more